Construction performance white wood cellulose fiber

Brand Topluse

Product origin Hebei,China

Delivery time 7 working days

Supply capacity 2000tons per months

The addition of wood fiber has a good effect on preventing coating cracking, improving water retention, improving production stability and construction suitability, increasing strength and enhancing adhesion to the surface.

WOOD FIBER

WOOD FIBER

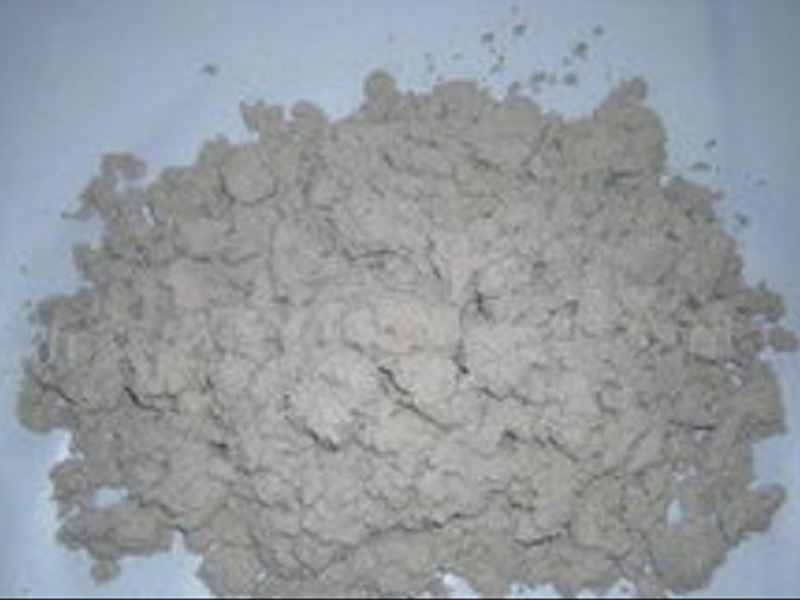

Grey Wood Cellulose Fiber

Lignin fiber is an organic fiber obtained by chemical treatment of natural wood, and its appearance is cotton wool-like, white or grayish white. Through screening, splitting, high-temperature treatment, bleaching, chemical treatment, neutralization and screening, fibers with different lengths and thicknesses can meet the needs of different application materials. Because the treatment temperature is above 250℃, it is a very chemically stable substance under normal conditions, and it is not corroded by ordinary solvents, acids and alkalis. It has the excellent quality of non-toxic, tasteless, pollution-free and non-radioactive, does not affect the environment and is harmless to human body, and belongs to green. The fiber microstructure is banded, uneven, porous and flat at the intersection, which has good toughness, dispersibility and chemical stability, strong water absorption and excellent thickening and crack resistance.

Technical Parameter:

Color | white | grey |

Bulk weight (g/L) | 190-240 | 250-280 |

Fiber length | 200um-300um | 500um |

PH Value | 7 | 7 |

Moisture | < 5.0% | < 5.0% |

Water retention | 850% | 700% |

Major Function

A. Preventing non-structural cracks caused by various plastic and mechanical shrinkage, segregation and other factors can increase the ductility of concrete in the plastic stage, thus effectively preventing the early shrinkage and settlement cracks.

B. In the hardening stage of concrete, the impact strength and fatigue strength of concrete are improved.

C. It can effectively reduce cracks, increase the continuity of materials and media, and reduce the phenomenon of local pressure concentration caused by the blocked shock wave.

D. It can absorb impact energy, especially after the initial crack, and at the same time it can make the crack width expand slowly.

E.It can prolong the service life of concrete and improve the ability to maintain the rigidity of concrete during fatigue.

F. The axial tensile strength and bending tensile strength of soil are improved.

Packaging, transportation and storage:

Product appearance: white flocculent, flaky and powdery solid. This product is non-dangerous, non-explosive, non-oxidizing, non-corrosive, non-radioactive and non-toxic.

1.Package

25 kg/paper bag or as your request.

2.Transport

Use clean transportation tools to protect against moisture, rain and sun. Handle with care to prevent scratching or breaking the package

3.Store

In a dry and well-ventilated room, the room temperature is 5-30℃. Please keep away from heat sources, keep away from humidity and avoid exposure to sunlight. It is forbidden to store it with volatile chemicals to prevent adsorption deterioration.

FAQ

Q1. Are you manufacturer or trading company?

We are manufacturer and we have import and export right.

Q2.Who are we?

We are based in Hebei, China, start from 2007,sell to North America(30.00%),Southeast Asia(24.00%),South Asia(15.00%),Mid East(10.00%),South America(8.00%),Eastern Europe(8.00%),Africa(5.00%).

Q3.How can you promise your quality is good?

Free sample provided for testing,but the buyer will afford the delivery freight cost. Besides, before delivery, each batch will be tested strictly, and retained sample will be kept in our stock to trace the variations of product quality.

Q4.What can you buy from us?

HPMC,MHEC,RDP,HEC,CMC,PVA,Titanium dioxide,pp fiber,wood cellulose fiber,HPS

Q5.What is your payment?

L/C at sight or T/T 30% in advance, 70% balance againest the copy of B/L.

Q6.What's your delivery time?

The production will be arranged after received deposit, after all payment is done, then arrange the shipment. Delivery time would be about 10-15days.